485 I/O Expansion Module -4/8/18 channels

Product model:

Classification:

Attachment Download:

Product Description

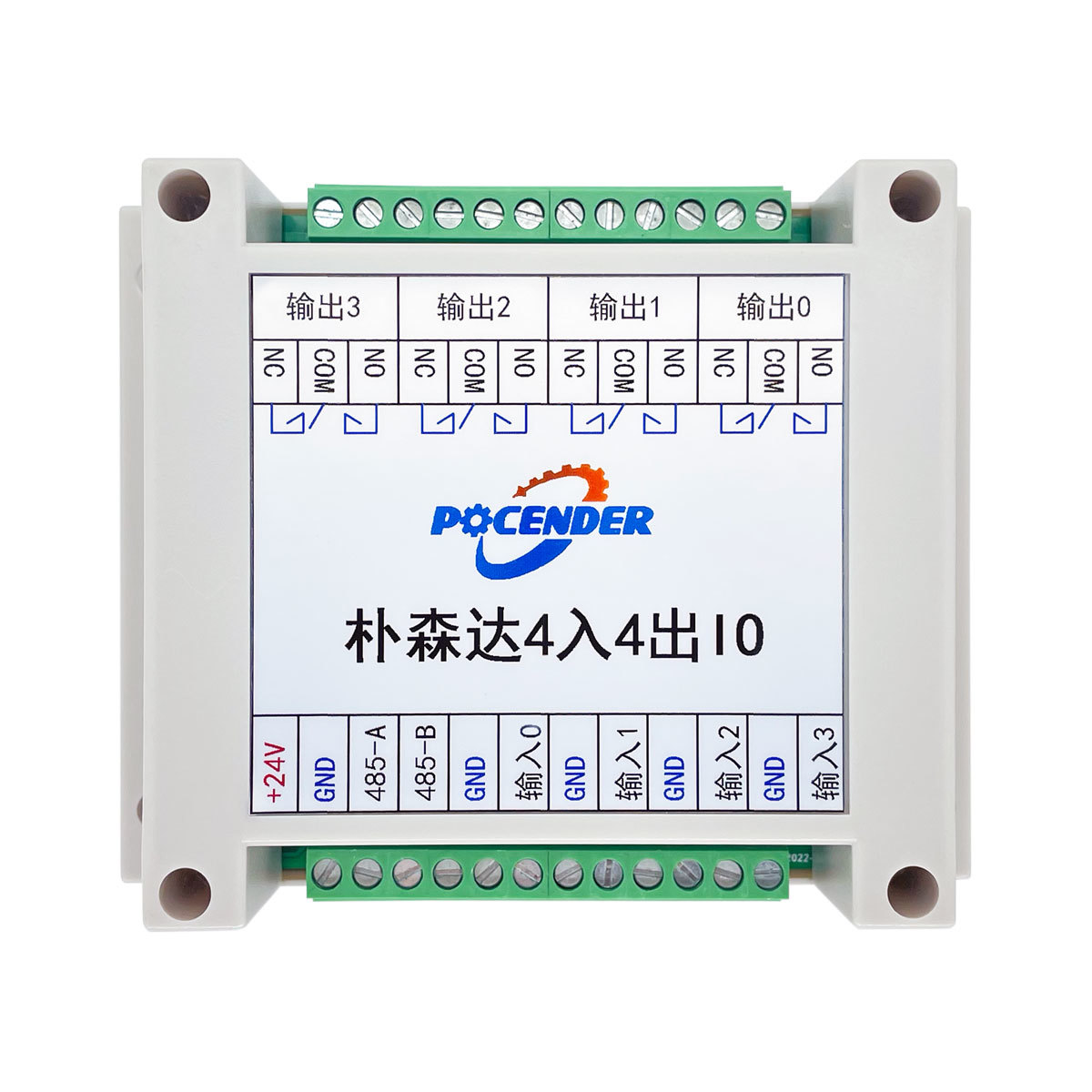

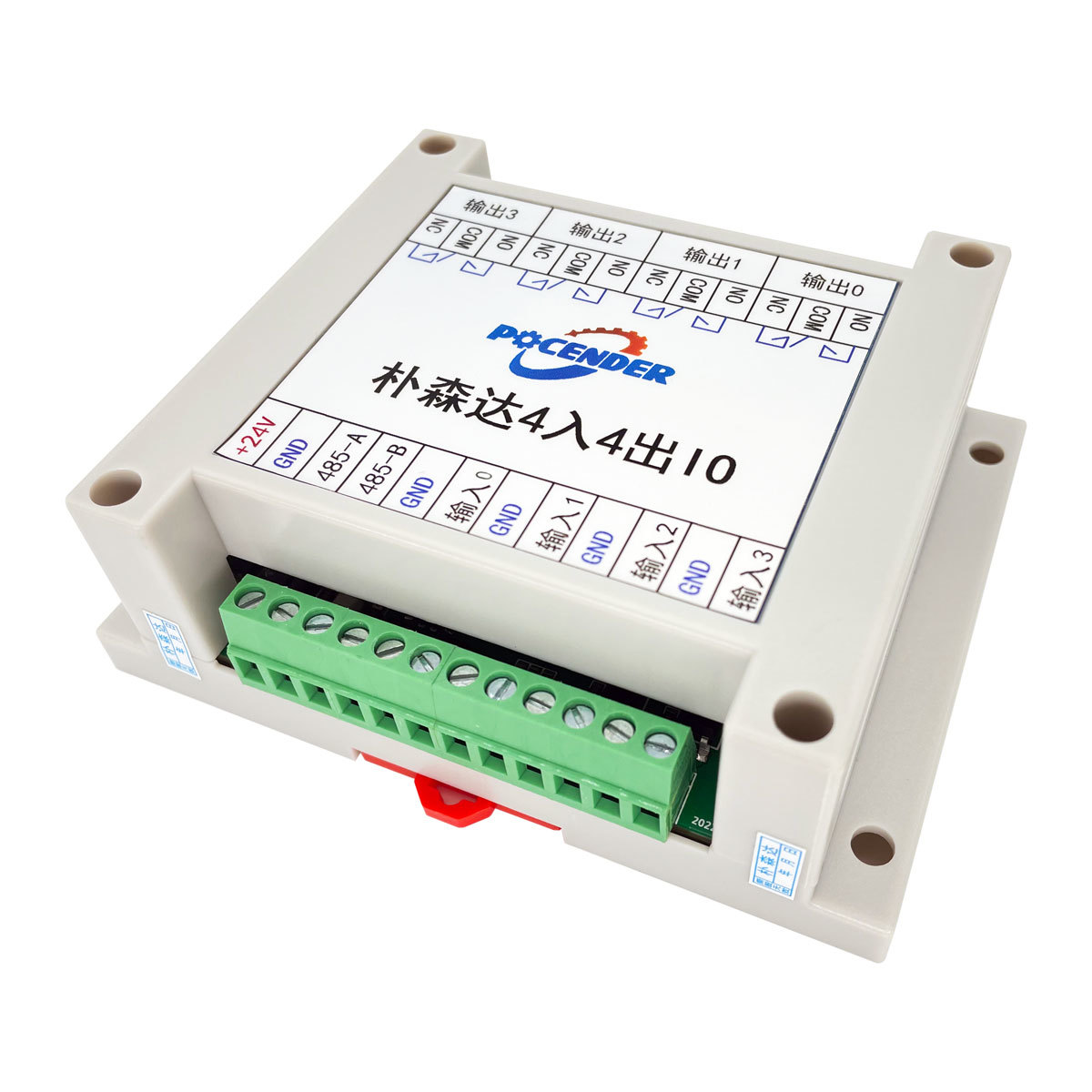

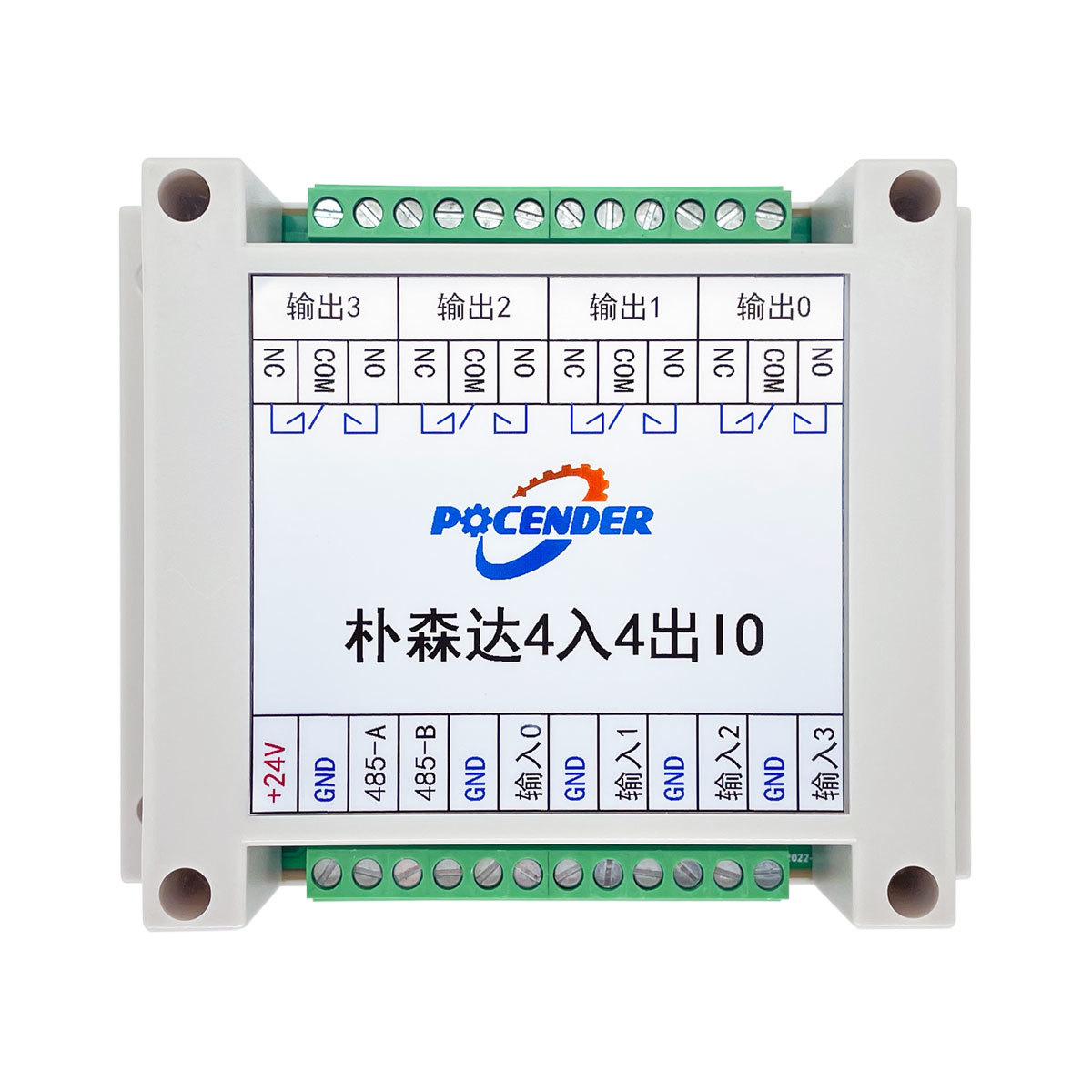

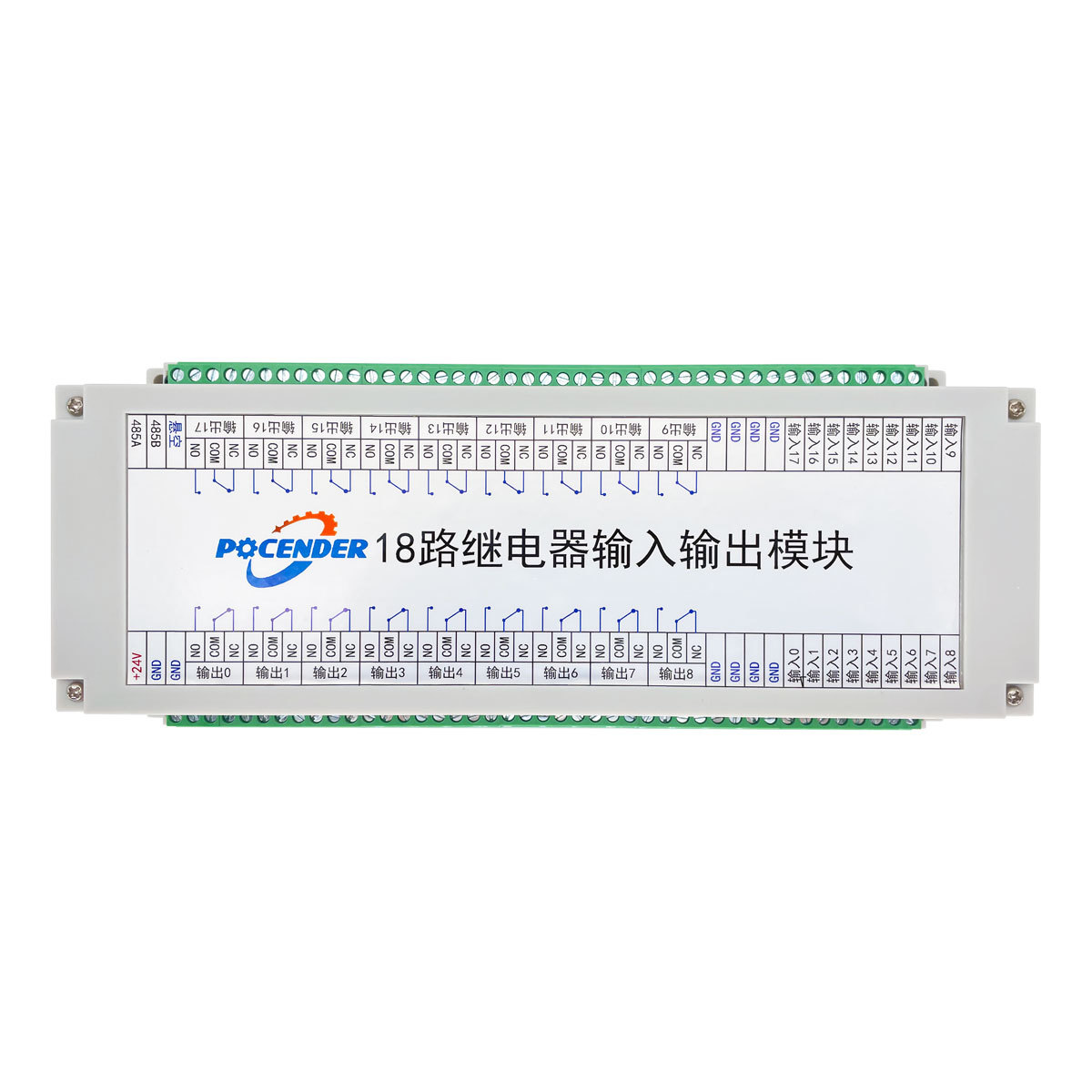

1.Product Dimensions and Appearance

1)4-Channel I/O Expansion Module: 115x90x40mm

2)8-Channel I/O Expansion Module: 155x100x50mm

3)18-Channel I/O Expansion Module: 250x110x65mm

2.Specifications

Supply Voltage: 12V DC / 24V DC

Lifespan: >100,000 cycles

Input Type: Opto-isolation

Input Voltage: 10~30V DC

Communication Interface: Isolated RS485

Communication Protocols: Standard/Extended Frames

Communication Distance: 0~1200 meters (can be extended using repeaters)

Baud Rates: 29600/14400/19200/38400/56000/57600/115200 BPS

Communication Address: Configurable from 1 to 255, with power-off memory retention

Parameter Reset: Reset button, software reset

Mounting Method: Standard 35mm DIN rail

Indicator Lights: Power/Communication/Input/Output

Protection Functions: Overcurrent/Overvoltage/Reverse Connection

Operating Temperature: -40°C to +85°C

Operating Humidity: 0% to 85% (non-condensing)

3.Functional Description:

1)Outputs (Up to 18 Channels):

Controlled by M Codes

M62P0-M62P15: Activate Outputs 0-15 (16 Channels in Total)

M63P0-M63P15: Deactivate Outputs 0-15 (16 Channels in Total)

2)Inputs (Up to 18 Channels):

Custom G-Code Functions (e.g., G0X0Y0)

Custom Functions for Start/Stop/Resume/Homing, and more

M Code Input Functions and Waiting for Input Features

Signal Inputs:

X0: Default for tool clamping cylinder safety detection.

X1: Default for tool disk ejection cylinder signal input detection.

X2-X9: Custom Button Inputs

Signal Outputs:

● Relay 0 is assigned to the tool engagement signal. Caution should be exercised.

● Relay 1 is assigned to the servo-driven tool magazine rack extension signal. Caution should be exercised.

● Relay 2 is assigned to the automatic switching signal between position mode and velocity mode for the servo spindle. Caution should be exercised.

● Relay 3 is assigned to the output signal for the chip door cylinder in the tool magazine. Caution should be exercised.

● Relay 9 is assigned to the air blow output signal for the tool setter. Caution should be exercised.

● Relay 10 is assigned to the alarm display signal for the tricolor lamp (red).

● Relay 11 is assigned to the pause/idle/manual output signal for the tricolor lamp (yellow).

● Relay 12 is assigned to the running signal output for the tricolor lamp (green).

Key words:

Standalone CNC Control System | CNC Control Programming OEM | CNC System Retrofit

Recommended Products

Product Consulting